Ronan Measure

Ronan Measurements Division: Radiometric Non-Contact Measurement

Ronan Measurements Division supplies the process control industry with leading-edge radiometric measurement systems that provide non-contact measurement solutions for the harshest environments. Everything we do is focused on helping you solve your most complex process measurement challenges.

Ronan offers a wide variety of Source Holder and Detector configurations, including Source and Source Holders to meet every need. Detectors configurable to any shape or length, and a Transmitter that is compatible with all the configurations and can be customized for special applications. With a philosophy of designing new products to be backward compatible, our customers have the confidence of an installed base of thousands of systems.

Radiometric measurement, also referred to as nuclear measurement, is a safe and effective non-contact method to measure liquids or solids in harsh process environments. Applications include:

- Continuous level

- Interface Level/Density

- Continuous Weight Measurement

- Point Level

- Density, Mass Flow

How does it work?

Radiometric measurement provides a safe and efficient, non-contact method to measure liquids or solids in harsh process environments. Each Ronan system is designed to deliver outstanding performance in a wide range of difficult applications and process conditions. The entire system mounts externally to the vessel or pipe and can be installed and maintained while the process is running without downtime, vessel modifications, risk of accidental release, or the need for specialty construction materials.

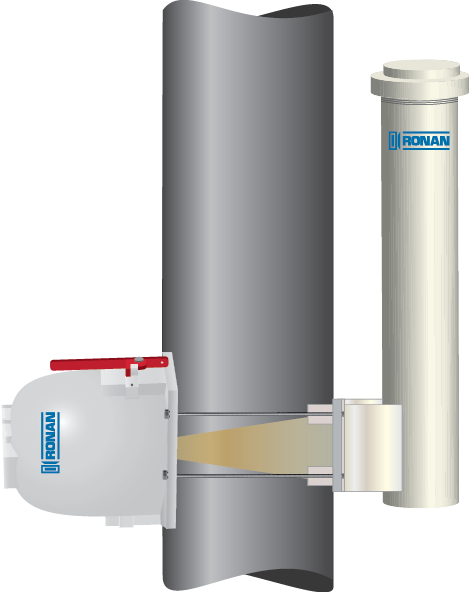

The illustration below shows a density measurement system mounted externally to the pipe. The gamma source holder (on the left) emits energy directed through the walls of the pipe and through the process in direction towards the detector mounted on the opposite side of the source. The detector measures the level of energy reaching it and sends a proportional signal to the microprocessor.

The systems utilize a single computer compatible with all Ronan detectors, which is easily expandable to accurately measure the most complex processes. The X96 microprocessor (seen in the picture below) filters and correlates this signal to a density/percent solids measurement. The user can select from a list of units of measurement for the desired reading. Because Ronan gauges use non-contact technology, there are no wetted parts to come into contact with the process, making it ideal for harsh installations such as: caustic, toxic, corrosive, explosive and carcinogenic processes irrespective of their solids content, viscosity and temperature.

Retrofitting

Ronan can help you retrofit your older systems while keeping your existing sources, giving you the ability to upgrade to the latest technology while avoiding disposal costs.

About

For more than 60 years, Ronan Engineering has manufactured reliable and leading-edge instrumentation systems. As providers of real-time monitoring and measurements of critical process control points, Ronan has kept some of the world’s largest plants, factories, hospitals and facilities running safely and efficiently. Ronan has established manufacturing, sales and service facilities in Kentucky and the United Kingdom.